A torque wrench is a precision tool designed to apply specific torque to fasteners, ensuring proper tightening without damage. Essential for various applications, it guarantees safety and accuracy.

What is a Torque Wrench?

A torque wrench is a precision tool designed to apply a specific amount of rotational force, or torque, to a fastener such as a nut or bolt. It ensures that the fastener is tightened to the exact specification required, preventing damage from over- or under-tightening. Available in manual, mechanical, or digital forms, torque wrenches are essential for various applications, from automotive repairs to industrial assembly. By providing precise control, they help maintain safety, durability, and performance in critical tasks. Proper use of a torque wrench minimizes the risk of component failure and ensures structural integrity. Always refer to the manufacturer’s guidelines for optimal results.

Importance of Using a Torque Wrench

Using a torque wrench is crucial for ensuring fasteners are tightened to the correct specification, preventing over-tightening or under-tightening. Over-tightening can damage threads or strip bolts, while under-tightening may lead to loose connections and safety hazards. A torque wrench ensures precision, promoting safety, durability, and performance in applications like automotive repairs and industrial assembly. It helps maintain structural integrity and prevents costly repairs by adhering to manufacturer guidelines. Proper torque application is essential for securing parts reliably and avoiding potential failures. Always use a torque wrench to meet specified torque values and ensure optimal results.

Safety Precautions

Always wear safety glasses and ensure the torque wrench is set correctly to avoid over-tightening. Use steady pressure and never push; pull to apply torque safely.

General Safety Guidelines

Always wear safety glasses and ensure the work area is clear of hazards. Use the torque wrench only as intended—never as a lever or hammer. Pull the wrench, do not push, to maintain control and avoid injury. Ensure the tool is properly calibrated and maintained. Over-tightening can damage components, so follow recommended torque values. Keep loose clothing and long hair tied back. Regularly inspect the wrench for wear or damage. Follow manufacturer instructions for operation and maintenance. Keep bystanders away while working. Proper usage ensures safety and prevents accidents. Always store the tool in a secure location when not in use.

Personal Protective Equipment

Always wear safety glasses or goggles to protect your eyes from flying debris. Use gloves to improve grip and prevent hand injuries. Wear steel-toe shoes to safeguard feet from heavy tools or falling objects. Ensure loose clothing and long hair are tied back to avoid entanglement. Avoid wearing jewelry that could interfere with tool operation. Proper protective equipment minimizes risks and ensures safe working conditions. Always inspect PPE for damage before use. Ensure gear fits properly to maintain dexterity and visibility. Following these guidelines helps prevent accidents and enhances overall safety while using a torque wrench.

Understanding the Torque Wrench

A torque wrench is a precision tool designed to apply specific torque to fasteners, ensuring proper tightening without damage. Crucial for automotive, industrial, and mechanical tasks.

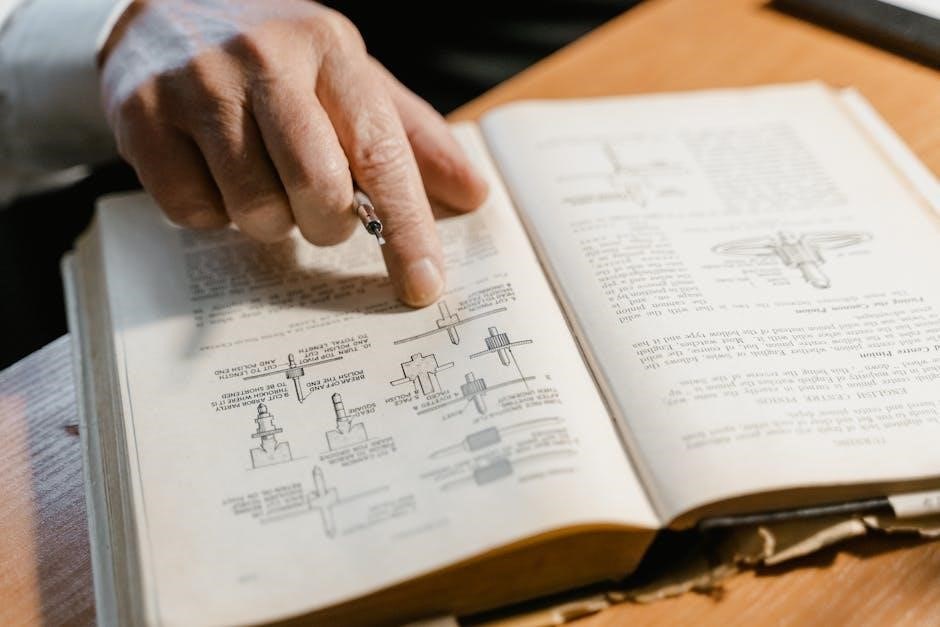

Components of a Torque Wrench

A torque wrench consists of a handle, shaft, and head, with a locking knob to secure settings. The handle provides grip, while the shaft transfers force. The head includes a ratchet mechanism for engaging fasteners. Mechanical wrenches feature a scale for torque adjustment, while digital versions have a display screen; Components work together to ensure precise torque application. Proper understanding of each part is essential for accurate use and maintenance. Regular inspection of these components ensures optimal performance and longevity of the tool.

Types of Torque Wrenches

Torque wrenches are available in various types, each designed for specific applications. Mechanical wrenches are the most common, featuring a scale and locking mechanism. Digital torque wrenches offer precise electronic torque control with a display screen for real-time readings. Hydraulic torque wrenches are used in heavy-duty industrial settings for high-torque applications. Adjustable wrenches allow users to set the desired torque, while fixed torque wrenches are pre-set for specific tasks. Each type is tailored to meet different requirements, ensuring accurate and efficient torque application across industries. Understanding the differences helps in selecting the right tool for the job.

Choosing the Right Torque Wrench

Selecting the correct torque wrench involves considering the specific task, bolt size, and required torque. Proper selection ensures safety and accuracy, preventing over-tightening or under-tightening.

Factors to Consider

When selecting a torque wrench, consider the torque capacity to match the bolt size and application. Choose between digital, mechanical, or hydraulic types based on precision needs. Handle length affects leverage, and adjustability allows versatility. Calibration is critical for accuracy, and durability ensures longevity. Weight and ergonomics impact comfort during use. Brand reputation and warranty are indicators of quality. Always refer to the manufacturer’s specifications to ensure compatibility with the task. Proper selection ensures safe and effective torque application.

Common Sizes and Applications

Torque wrenches come in various sizes to suit different tasks. Common drive sizes include 1/4″, 3/8″, and 1/2″, with torque capacities ranging from 10 Nm to 300 Nm. They are widely used in automotive for wheel lug nuts and engine repairs. In industrial settings, they are essential for machinery assembly and maintenance. For construction, they secure bolts on heavy equipment. Smaller wrenches are ideal for precision tasks, while larger ones handle heavy-duty applications. Selecting the right size ensures proper fitment and accurate torque delivery for safe and reliable results.

Using the Torque Wrench

Attach the socket, set the torque value, and apply steady pressure to tighten the fastener accurately and safely with the wrench. Ensure proper fitment and alignment always.

Step-by-Step Guide

Enter the Torque Value: Set the wrench to the desired torque using the manufacturer’s instructions. Ensure the value matches the fastener’s specifications.

Attach the Socket: Securely fit the appropriate socket to the wrench head, ensuring it aligns perfectly with the bolt or nut.

Apply Steady Pressure: Hold the wrench firmly, grasp the handle centered, and apply consistent force without jerking or pushing at an angle.

Check the Torque: After tightening, verify the torque setting to ensure accuracy and avoid over-tightening, which can damage the fastener.

Adjust as Needed: If the torque is incorrect, re-adjust the wrench and reapply until the desired torque is achieved.

Store Properly: After use, reset the wrench to its lowest setting to maintain calibration and prevent damage.

Setting the Torque Value

To set the torque value, locate the adjustment mechanism on the wrench, typically a locking knob or scale. Rotate the handle to align the desired torque marking with the indicator. For digital models, use the buttons to input the exact value. Always refer to the manufacturer’s instructions for specific adjustment procedures. Once set, tighten the locking mechanism to secure the torque value. After use, reset the wrench to its minimum torque setting to maintain calibration. Ensure the torque value matches the fastener’s specifications to avoid damage or under-tightening.

Attaching Sockets

Attach the appropriate socket to the torque wrench by aligning the drive size with the wrench’s square drive. Ensure the socket is securely seated and clicks into place. For manual wrenches, slide the socket over the anvil and twist gently to secure. For digital models, follow the manufacturer’s guide for attachment. Always use sockets that match the fastener size to prevent rounding or damage. If using an extension, ensure it is compatible with the wrench’s drive system. After attachment, double-check the socket’s fitment before applying torque. Wearing safety goggles is recommended during this process.

Applying Torque

Hold the torque wrench firmly with both hands, ensuring a steady grip. Apply gentle, consistent pressure in a clockwise direction for tightening. Avoid jerky movements or excessive force. For click-type wrenches, listen for the distinct “click” sound, indicating the set torque has been reached. For digital models, wait for the beep or light signal. Always pull the wrench toward you, never push, to maintain control. Wear safety goggles to protect against potential fastener failure. Ensure the wrench is held at the center of the handle for optimal leverage. If the wrench has an adjustable handle, use the longest comfortable length for smoother operation. Stop immediately once the desired torque is achieved. If using extensions or adapters, ensure they are rated for the applied torque to prevent damage. Always operate within the wrench’s torque capacity range to avoid overloading the tool. This ensures accurate torque application and extends the tool’s lifespan.

Checking Final Torque

After applying torque, recheck the fastener to ensure the specified value has been achieved. For click-type wrenches, listen for the audible “click” sound. For digital models, confirm the target torque is reached via the display. Always recheck torque with the wrench set to the correct orientation and socket size. Wear safety goggles during this process. Ensure the wrench is held firmly and evenly to avoid slippage. If the torque reading differs, adjust and reapply torque carefully. Never exceed the recommended torque value, as this can damage the fastener or surrounding material. Double-checking ensures accuracy and prevents over-tightening or under-tightening, which can lead to equipment failure. Always refer to the manufacturer’s instructions for precise verification methods. Proper final torque checks are crucial for safety and durability in any application.

Maintenance and Calibration

Regular maintenance ensures accuracy and longevity. Store torque wrenches properly, clean them, and avoid exposure to harsh conditions. Calibrate annually or as specified.

Regular Maintenance Tips

To ensure optimal performance, regular maintenance of your torque wrench is crucial. Always store it in a dry, clean environment, away from direct sunlight and moisture. After use, adjust the wrench to its lowest torque setting to relieve internal spring tension. Clean the tool with a soft cloth, avoiding harsh chemicals. Never apply excessive force or use the wrench as a hammer, as this can damage internal components. Check for wear on moving parts and lubricate hinges periodically. Regularly inspect the socket drive for damage or rust. Proper care extends the tool’s lifespan and maintains accuracy.

Calibration Process

The calibration process ensures your torque wrench delivers accurate readings. Begin by setting the wrench to its minimum torque value. Next, attach it to a torque tester or similar device. Apply steady, centered pressure until the wrench clicks or triggers, indicating the torque has been reached. Repeat this process at least three times to verify consistency. If deviations are found, adjust the wrench according to the manufacturer’s instructions. Calibration should be performed annually or after prolonged storage. Always refer to the user manual for specific calibration steps tailored to your tool. Proper calibration ensures precise torque application.

Troubleshooting Common Issues

Common issues with torque wrenches include inaccurate readings, slipping, or failure to engage. Regular maintenance and calibration can prevent these problems. Always follow manufacturer guidelines.

Identifying and Solving Problems

When using a torque wrench, common issues include inaccurate torque readings, slipping, or failure to engage. To address these, first identify the root cause. For inaccuracies, recalibrate the wrench. If slipping occurs, ensure the socket is properly attached. For engagement issues, check the tool’s condition and adjust the torque setting. Regular maintenance, such as cleaning and lubricating moving parts, can prevent these problems. Always refer to the manufacturer’s guidelines for troubleshooting specific models. Addressing issues promptly ensures precise torque application and extends the tool’s lifespan.